Most homes in the UK have a complex network of water pipes. Insulating this pipework is called lagging and by sealing in heat, it saves energy and has a host of other benefits too. To protect water pipes around your home you will require pipe lagging or insulation. This simply means adding insulation to the water pipes around your home as it prevents them from freezing be it piping inside the home or outside. It also helps exposed hot water pipes to retain their heat when running through those unheated parts of the house.

Pipe insulation materials

- Polyethylene (flexible plastic foamed insulation) – Probably the most widely used type of pipe insulation.

- Mineral/glass wool – A good thermal, acoustic and fire-retardant lagging. Does not shrink, swell, rot or burn, so is a very popular choice.

- Flexible elastomeric foam – A rubber-like material, highly resistant to the passage of water vapour and has great thermal properties

- Rigid foam – normally used for industrial buildings, for the really large pipes. Not widely available for homes.

So how does lagging help and what are the benefits for my home?

Energy saving

Pipe insulation can provide significant energy savings by preventing heat (or cold) loss by introducing a thermal resistance and reducing heat flow from the pipe to the outside air. A very well-insulated pipework system will help cut down on running costs and save ultimately on maintenance. The Thicknesses of thermal pipe insulation used for saving energy can vary, but as a general rule, pipes operating in more-extreme temperatures exhibit a greater heat flow and larger thicknesses are required for a greater potential savings.

Reduces Noise Pollution

Lagging can reduce and help limit unwanted noise. Pipework can operate as an amplifier for sounds to travel from one part of a building to another or throughout a home. Acoustic insulation can prevent this by ‘dampening’ the pipe wall wherever the pipe passes through a fixed wall or floor and wherever the pipe is mechanically fixed and reduce unwanted noise. Pipes radiate mechanical noise or you can hear the water passing through them, especially if you have thin walls. So by putting something over the top can help muffle that annoying sound, Insulation and lagging can form areally good sound barrier.

Safety

When it comes to health and safety exposed metal pipework can reach highly extreme temperatures of hot or of cold. Insulating these pipes means that people are less likely to injure or hurt themselves if they were to come into contact with these pipes. So by adding lagging this can reduce those risks.

No Burst Pipes

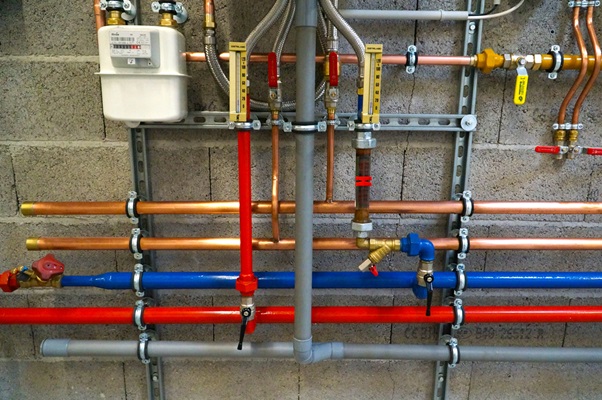

Copper’s high conductivity means that it is great for transporting hot water in central heating systems, but just as the pipes can get very, very warm, they can also get extremely cold too. So, when water freezes, pipes can have the potential to burst, leading to very expensive repair work, so by using lagging around the pipes you can reduce such things from happening.

Corrosion

Pipes in very cold environments can attract water vapour. When this condenses on the surface of the pipe, it can lead to corrosion. It can also potentially cause damp within the surrounding walls. By using insulation or lagging this prevents this by simply raising the surface temperature of the pipe and hence forming a water-vapour barrier.